Frame Construction

- Superior construction grade spruce plywood is dried better so it doesn’t warp or crack.

- We combine materials and make selections based on the application to ensure the strength and durability of our furniture. The wood pieces systematically interlock during the assembly process to create a strong, reinforced structure.

- For areas of the frame that need to withstand more pressure, TimberStrand® is used. An engineered wood used for its strength which will not change due to humidity or temperature.

- Our frames have a “L” shaped piece that connects the back of the arm to the seat. It works to stop pivot point on the joint and reinforces the frame.

Back Rest Construction

- All the backs of our reclining furniture are removable to make moving and placing the furniture easier.

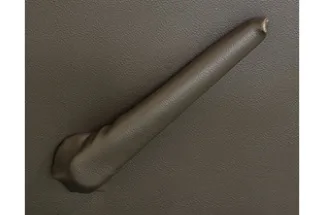

Mechanism

- Exclusivity on the design of the mechanism.

- We are constantly innovating on the design of our mechanisms to enhance performance, fluidity of motion and function.

- Manufactured in the United States, we invest more in our mechanisms by using a thicker grade metal for increased quality and durability.

- The use of self-tapping screws reduces the risk of loose fastenings because they actually bite into the metal.

- Adjustable legs on rocking chairs.

- Swivel bases available on most rocking chairs.

Foam and Filling

- High quality density foam (2.05 lb/ft³). The competition uses between 1.5 and 1.9 lb/ft³.

- The compression of the foam provides flexibility and comfort.

- We use pre-crushed foam to allow for better comfort from the moment you receive your furniture.

- We use high quality No-Sag® springs linked by a metal rod used for better weight distribution.

- Felt is installed over the springs to protect the foam and make them last longer.

- Only 100% new polyester fiber is used in the manufacture of your furniture.

- We use curled fiber for better resiliency, and because it retains its shape for longer (6 ripples per inch).

- Fibers are silicone treated to avoid bunching up.

- Fibers are hollow like a straw to allow air to flow through to create more abundance.

- No recycled fibers are used because they do not provide good resiliency.